Magnetic flow meters, also known as mag meters, play a crucial role in various industrial processes across India. These devices have revolutionized the industrial sector in the country, especially in areas such as water treatment, chemical processing, and food and beverage production. This article delves into the impact of these flow meters on industrial operations in India, discussing their advantages, uses, and future trends.

Understanding Magnetic Flow Meters

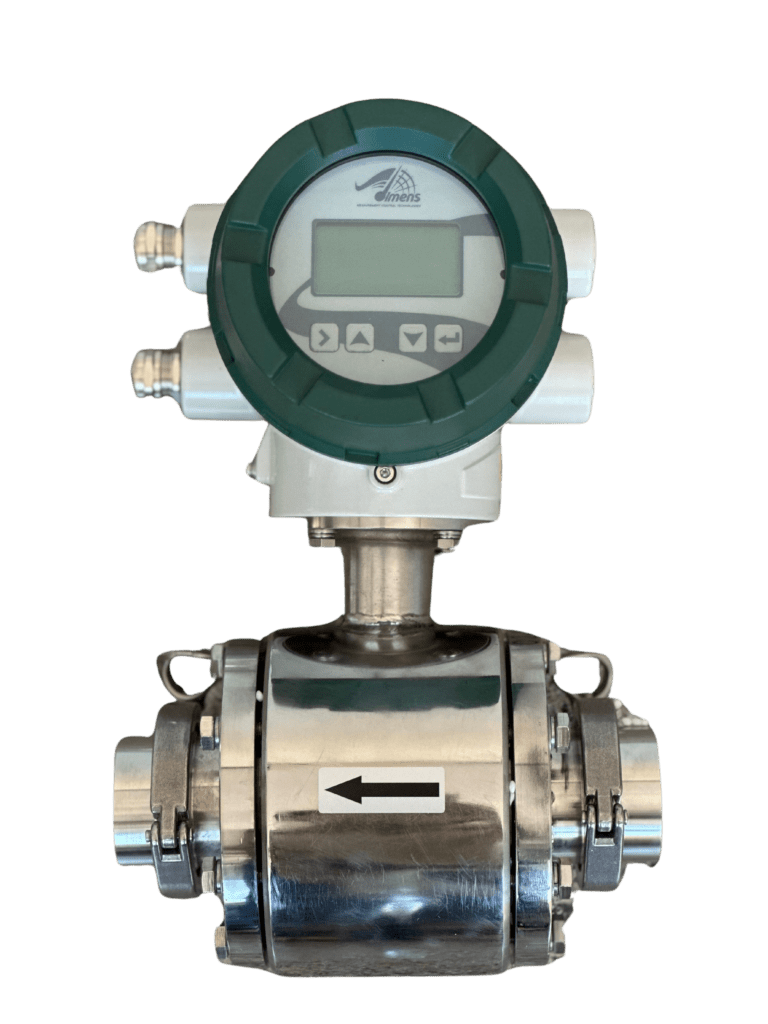

These flow meters function by utilizing Faraday’s Law of Electromagnetic Induction to gauge the flow rate of conductive liquids. As a conductive fluid moves through a magnetic field, it generates a voltage that is directly proportional to the flow velocity, enabling precise flow measurement.

Key Features:

- Non-intrusive Measurement: Magnetic flow meters do not have any moving parts, resulting in minimal pressure drop and no flow blockage.

- High Accuracy: These devices typically offer an accuracy level within ±0.5% of the flow rate.

- Versatility: They are suitable for a wide range of applications.

Impact on Industrial Processes in India

India’s industrial sector benefits greatly from the implementation of these devices in several key areas:

- Water Treatment: In India’s water treatment facilities, accurate flow measurement is essential for monitoring and controlling water distribution. These meters are used to measure both raw and treated water flows, leading to better resource management and operational cost savings.

- Chemical Processing: Chemical plants in India leverage these meters to handle aggressive and corrosive fluids. The non-intrusive design prevents contamination, making them ideal for processes requiring high purity and precision.

- Food and Beverage Production: The food and beverage industry in India requires stringent hygiene standards and precise measurement of ingredients. These devices help maintain these standards by providing accurate measurements without direct contact with the fluids, ensuring product quality and safety.

Advantages Over Other Flow Meters

Compared to other flow measurement technologies, these meters offer several advantages:

- Maintenance-Free Operation: The absence of moving parts reduces maintenance needs and extends the lifespan of the devices.

- Wide Range of Applications: They are effective with various fluid types and are unaffected by changes in temperature, pressure, or viscosity.

- Environmental Benefits: Accurate measurements enable process optimization and waste reduction, contributing to sustainable industrial practices.

Future Trends and Innovations

The future of these meters in India is promising, with ongoing advancements in technology enhancing their efficiency and applicability:

- Enhanced Data Analytics: Advanced algorithms can analyze flow data in real-time, offering insights for improved process control and optimization.

- Remote Monitoring: IoT-enabled devices allow for remote monitoring and control, reducing downtime and enhancing operational efficiency.

- Integration with Industrial Automation: As industries in India continue to embrace automation, these meters will play a crucial role in ensuring precise flow measurements and seamless integration into automated systems.

Magnetic flow meters are revolutionizing industrial processes in India by providing accurate, reliable, and maintenance-free flow measurement solutions. Their application across various industries, from water treatment to chemical processing and food production, underscores their versatility and importance. With advancements in technology, these devices will become even more integral to industrial operations, driving efficiency and sustainability.

Dimens is proud to offer a range of these flow meters and other measurement devices to clients across India. Our extensive product line includes state-of-the-art meters designed to meet the diverse needs of various industries, from water treatment facilities to chemical processing plants and food production units. Our commitment to quality and precision has earned us a strong client base in the region, helping businesses optimize their processes and achieve greater operational success. We provide comprehensive support, including installation, calibration, and maintenance services, ensuring that our clients receive the best possible performance from their measurement devices. With our cutting-edge technology and dedicated customer service, Dimens continues to set the standard for excellence in industrial measurement solutions in India.